The industrial asset management R&D has a strong tradition of industrially oriented and applied R&D work on smart industrial assets and complex systems, integrated operations and modern maintenance process, as well as condition monitoring and intelligent maintenance interventions.

The R&D activities on Industrial Asset Management aim at enabling modern industrial transformation in both offshore and land-based industrial sectors, as well as in the public sector, with a focus on Industry 4.0, digitalisation, sustainability, and green transition to enhance asset integrity, dependability, and resilience.

Reliability, operability, maintainability, and technical & safety integrity characteristics of any industrial asset (i.e. production plants, process facilities, energy production and distribution systems, machines and equipment, infrastructure and civil structures, public transport, maritime, construction, etc.) have direct effects on economics, safety & security, societal impact, as well as sustainability and environmental impact in all industrial sectors. Those issues are even more critical when Industry 4.0, Internet of Things, digitalisation, and green transition change the future of industrial assets and public infrastructures.

The R&D work on Industrial Asset Management mainly cover three main tracks:

- Smart industrial assets, complex industrial systems, and digital infrastructures

- Integrated operations, modern maintenance process, and smart asset support capabilities

- Condition monitoring, predictive analytics, and intelligent maintenance interventions

The R&D work on industrial asset management has a long tradition for practical industrial orientation in R&D activities in close collaboration with various industrial sectors. The relevant sectors include;

- Oil & gas production, processing, and distribution

- Offshore wind energy farms

- Clean energy sources and transmission systems

- Civil structures and public infrastructures

- Manufacturing, production and process facilities

- Smart cities, transport, and logistics

- Engineering education and innovation

R&D profile

Smart industrial assets, complex industrial systems, and digital infrastructures

R&D activities in this track have a main focus on practical issues and challenges under modern asset digitalisation processes, inter-dependent industrial asset contexts, complex systems approach to modern industrial assets, as well as smart asset management and operational models under uncertain conditions from the perspectives of asset integrity, dependability, resilience, as well as competitive asset performance.

Some selected R&D projects on this track include;

- Sustainable Value Creation in Manufacturing Networks, EU project

- Operations and maintenance performance in oil and gas production assets: theoretical architecture and capital value theory in perspective, PhD thesis, Jayantha P. Liyanage

- Managing environmental sustainability in Seaports: Towards an Integrated method, PhD project, Alsnosy Balbaa

- Simulation based decision support for engineering assets: an agent-based approach for operation and maintenance of offshore wind farms, PhD project, Ole-Erik V. Endrerud. This project led to the spin-off company Shoreline Wind AS

- RAMSI management model and evaluation criteria for Nordic offshore wind asset

- Implementing best practices, knowledge, competences, and technology for safe and efficient asset management of tunnel industry, PhD Project, Syed Taha

- Data-driven solutions for resilient offshore wind energy assets, PhD project, Shambu Jaykumar (ongoing)

Integrated operations, modern maintenance process, and smart asset support capabilities

This R&D track perform in-depth studies on practical issues and challenges related to remote operations and decision support, industrial work processes, reliable and safe operations, data-driven operational and maintenance practices, industrial logistics and intralogistics operations with automation and digitalization, as well as organizational issues under complex operational and maintenance conditions related to both conventional assets as well as assets under digital transformation.

Some selected R&D projects on this track include;

- Technical integrity and Operations & Maintenance performance: Optimization through Data and Organizational intelligence in an Integrated environment, PhD project, Jawad Raza

- Collaborative work processes in Integrated oil & gas production environments: Development and deployment of Integrated planning, PhD project, Yu Bai

- Analysis and Management of Bottlenecks in Supply networks, PhD project, Jakob E. Beer

- Safety instrumented systems in Low demand mode in Oil & Gas production process: Data-driven decision support for improvements in Operations and Maintenance practice, PhD project, Pengyu Zhu

- Early sensing and Advanced situation awareness to enhance Operational resilience for mitigating unwanted events and incidents in Industrial assets, PhD project, Mohammad Bakhshandeh (ongoing)

- Evaluating the Impact on Patient Flow in the Emergency Department during Pandemic Conditions : A multi-agent hybrid simulation approach, PhD project, Gaute Terning (ongoing)

Condition monitoring, predictive analytics, and intelligent maintenance interventions

The R&D work on this track has a main focus on practical issues and challenges in terms of diagnostics and prognostics, reliability, technical and safety integrity, as well as predictive analytics for risk-based and smart maintenance interventions in technical systems, engineering equipment, and components of Industrial assets in various lifecycle phases. This track also explores modern inspection and maintenance practices for life extension, re-use, and recycling purposes.

Some selected R&D projects on this track include;

- Modelling and Simulation for Intelligent Maintenance: A Case Study on Centrifugal Gas Export Compressor in Oil & Gas Transport System, PhD project, Helge Nordal

- Predictive maintenance for blade erosion in wind turbines, PhD project, Waqar Ali (ongoing)

Lab facilities

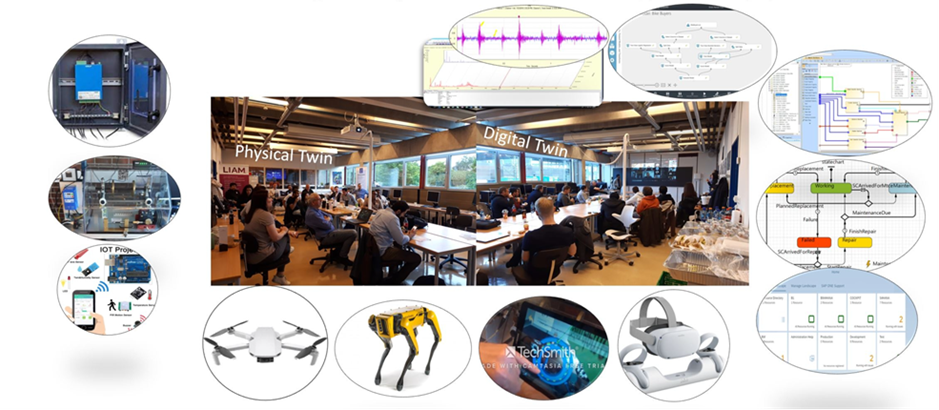

IAMLAB, at KE C-285 and C-289, is a cyber-physical lab that:

- Enables students to understand and gain hands-on condition monitoring and diagnostic techniques.

- Provides a physical fault simulator to experimentally research the most common industrial faults and the ways to detect, diagnose and prognosis such faults.

- Provides physical counterpart and instrumentations to perform digital twin building, augmentation and virtualisation tasks.

- Provides a digital environment to utilise:

- Model-based systems engineering software

- Industrial simulation models and prescriptive analytics

- Predictive analytics using Jupyter, Azure ML, Matlab PdM

- RAM analytics software

- Plant Maintenance Management (SAP HAHA)

- Provides a small-scale Arduino and Azure workshop for student projects.

More about the lab

As an integral part of the Master’s programme in Industrial Asset Management, IAMLAB bridges theory and practice by offering a hands-on, research-driven environment for students and researchers.

The lab is designed to equip students with the competencies required for modern asset management, condition monitoring, and predictive maintenance across industrial sectors.

IAMLAB supports experiential learning through advanced physical and digital infrastructure. Students gain direct exposure to diagnostic techniques using a fully equipped fault simulator, capable of replicating real-world faults such as imbalance, misalignment, bent shafts, and bearing or gear defects. Integrated with SKF IMX8 monitoring systems and SKF @ptitude Analyst software, the simulator enables both learning and experimental research in fault detection, diagnosis, and prognosis.

In addition, the lab provides facilities for building and validating Digital Twins, supported by augmentation and virtualization tools. A comprehensive suite of industry-standard software, such as CAMEO Systems Modeller (MBSE), AnyLogic (industrial simulation and prescriptive analytics), Matlab and Azure ML (predictive analytics), Miriam (RAM analytics), and Hexagon (Asset and maintenance management), ensures students develop digital and analytical fluency.

IAMLAB also nurtures innovation through a small-scale Arduino and Azure-based workshop, encouraging students to prototype novel solutions. With its combined physical spaces (KE C-285 and C-289) and digital environments, IAMLAB plays a central role in fostering robust, future-oriented asset management education, training, and practical learning.