The Faculty of Science and Technology at UiS has several laboratories within the field of construction and building materials. Here is an overview of relevant equipment and facilities.

These study programmes use the laboratories in teaching:

Mechanical workshop

The mechanical workshop has equipment for joining, cutting, folding, bending and removing chips from materials. We can help machine materials used for experiments that require a high degree of accuracy and produce special parts for equipment that cannot be obtained elsewhere. We can make parts in most types of plastics and metals.

Equipment that is produced or adapted for a specific purpose is often refined during the fabrication process and this usually takes place through a continuous dialogue with the orderer. The workshop is available for both research and teaching and for use by both students and staff.

Kontaktperson: Emil Mannes Surnevik

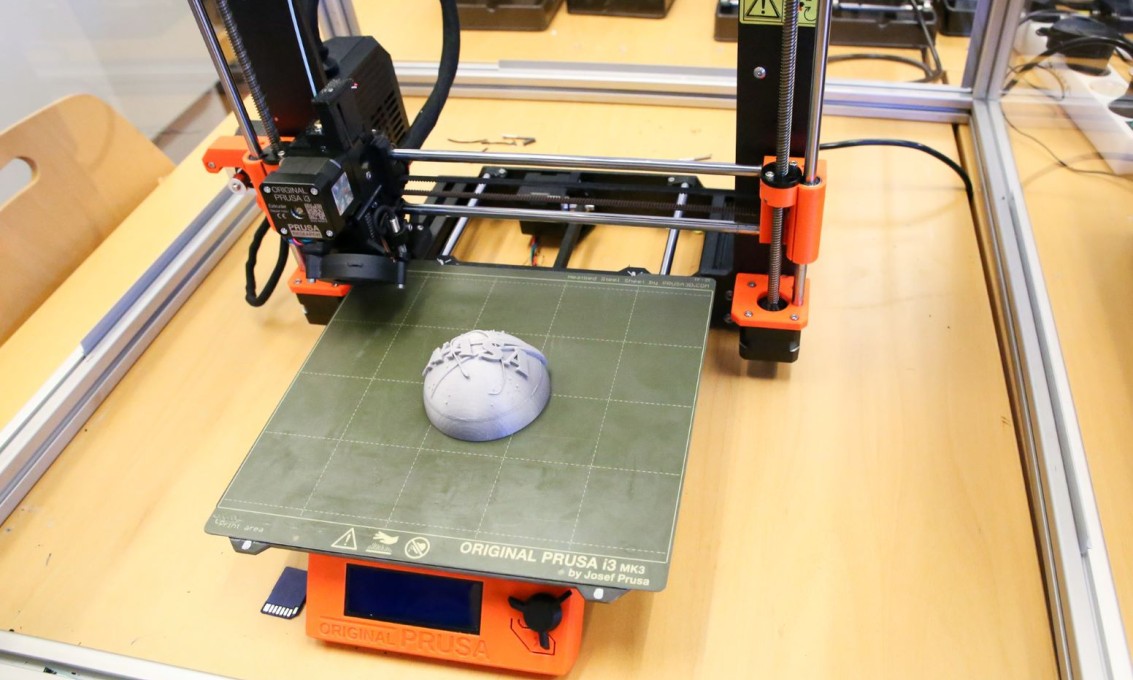

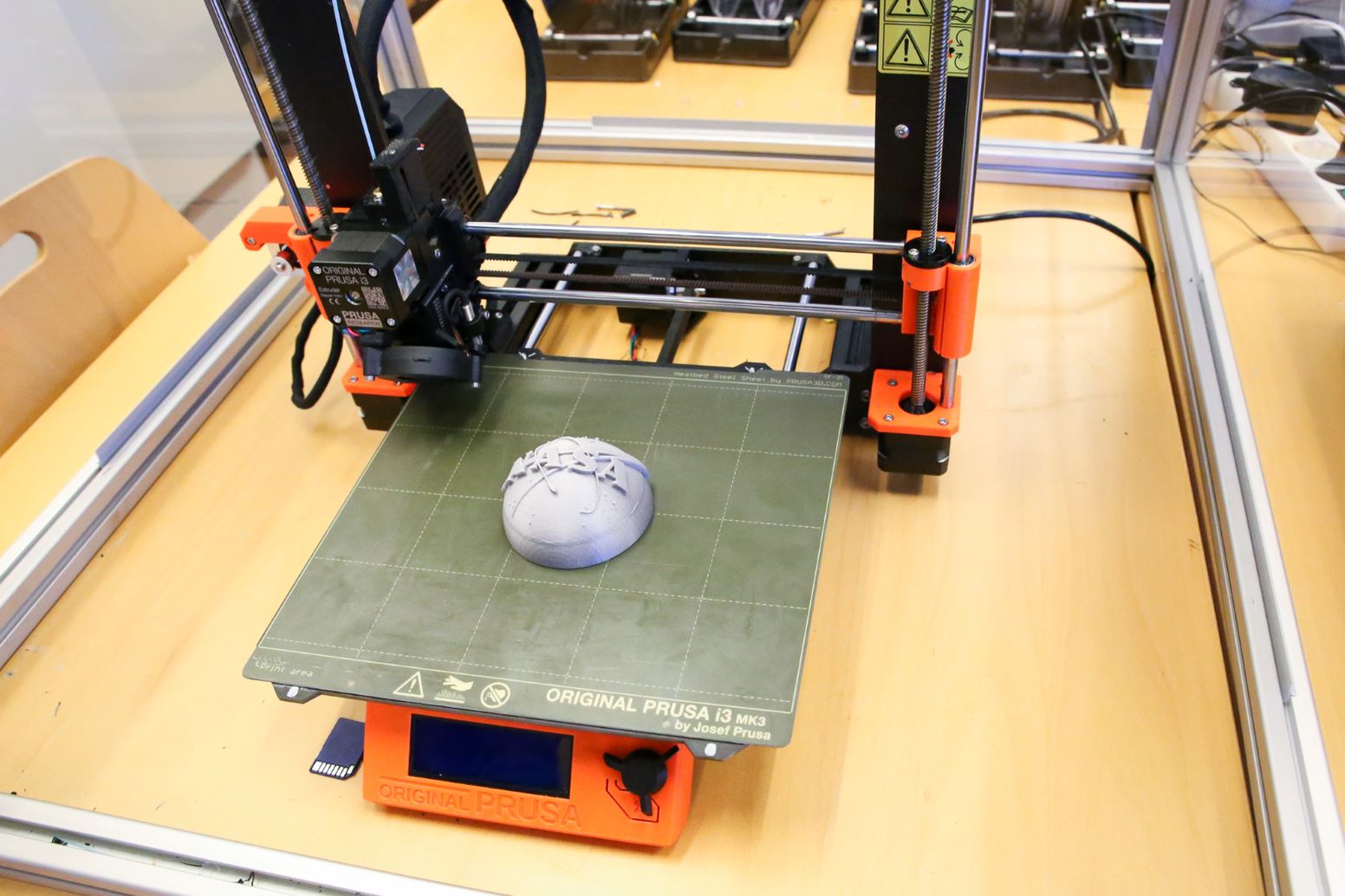

3D-printing

The 3D printing laboratory has equipment for 3D printing parts in various types of plastic, such as ABS, PLA and TPU, and an FDM metal printer, which are used for laboratory work by students and for research. There are also 3D printers for biomedical research. DLP printing available, Digital light processing for Lumen X printer.

The parts produced vary from prototypes to display models. The facilities are used by both students and staff and are also used in subjects like CAD/CAP and 3D Printing.

Contact persons: Jan-Tore Jakobsen, Andreas Skaare, og Hanne Røland Hagland (bioprinting)

Concrete

The laboratory has equipment for producing concrete and equipment for carrying out tests on concrete in both fresh and hardened states based on NS-EN standards.

Contact persons: Jarle Berge og Samdar Kakay

Wood

The faculty has its own wood workshop. The workshop has large benches and some tools that can be used for, for example, building models. It also has machines and equipment that are used by students and staff for project assignments, such as a laser cutter and various saws.

Contact person: Andreas Skaare

Roadbuilding

The roadbuilding laboratories can be used for analysing and testing aggregates, bitumen, bituminous masses and asphalt. Asphalt masses can also be produced, with the preparation and compaction of samples. The equipment and facilities are used by students and staff, as well as external companies that order testing and reports on various roadbuilding materials that will be used in Rogaland.

The laboratory has equipment for heating bitumen samples, and it can conduct Fraass breaking point tests (the temperature at which bitumen reaches critical brittleness and cracks), softening point tests (the temperature at which binders, under standardised conditions, achieve a certain viscosity) as well as needle penetration tests (which determine the hardness of bitumen and bituminous binders by measuring the penetration of a needle into the sample). In the laboratory, users can also prepare asphalt samples with an asphalt mixer before testing the asphalt through Marshall impact compaction (the samples are placed in a cylindrical form (90 mm diameter) and compacted with a Marshall compactor to a length of approximately 90 mm. In addition, users can determine the indirect tensile strength and load distribution coefficient of bituminous masses, as well as the sample’s density, and calculate bitumen content.

For aggregates, users can crush and split stone samples and rocks into smaller, representative fractions. The density of aggregates can be determined using water baths and steel pycnometers. Sieve shaker analysis is used for grading aggregate materials and can be used for all aggregates from 0.063 mm to 90 mm, while sedimentation tests use a hydrometer to grade aggregate materials smaller than 0.063 mm.

Contact person: Guzmán Cruz

You might also be interested in:

Enhancing efficiency and sustainability in Lean Management

Daria Larsson defended her PhD thesis at University of Stavanger 11 April 2025.

Numerical modeling of monopile foundation removal process for offshore wind turbines

Soheil Salahshour Langeroodi conducted research on numerical modeling and analysis of offshore monopile foundation remov...

Research on urban wind and pedestrian wind comfort

Trond-Ola Hågbø defended his PhD thesis with the title “Towards Realistic and Efficient Computational Fluid Dynamics Sim...

Successful completion for PhDs at UiS' partner university

Together with Wallaga University in Ethiopia, UiS is part of the education project INDMEET (Institutional Network for De...

Design, Modelling and Analysis of Combined Wind and Wave Energy Systems for Intermediate Water Depths

Chern Fong Lee has conducted research on the numerical modelling of Combined Wind and Wave Energy Systems for Intermedia...

Celebrating PhD achievements in circular economy and supply chain innovation

Noorhan Firdaus Pambudi and Kartika Nur Alfina have successfully completed their doctoral projects in the Department of ...

Yara's Birkeland Prize 2024 to Song Lu

Yara’s Birkeland Prize for 2024 in chemistry was given to doctor Song Lu for his thesis titled “Transition-metal-mediate...

Design optimisation for floating offshore wind turbines

Anja Schnepf defended her PhD-thesis titled "Design optimisation of Power Cable Configurations for Floating Offshore Win...

He has 3D printed a training model for spinal anesthesia

Øyvind Time's master's thesis can help make everyday life easier for healthcare personnel who must learn how to take a f...

Numerical modelling of floating docks

Jianan Zhang has performed research on the numerical modelling of the floating docks. On 31 May, she defended her doctor...

Successful UiS Aerospace rocket launch

The UiS Aerospace rocket launch took place successfully 27 April in Helleland.

Design of autonomous underwater vehicles

Yucong Ma has researched dynamic analysis and design of subsea shuttle tanker systems.

Receives award for innovation in computing

Professor Dimitrios G. Pavlou was recently awarded the prestigious Hojjat Adeli Award for Innovation in Computing.

Their article in Physics of Fluids was selected as “Featured Article”

Physics of Fluids (PoF) belongs to American Institute of Physics (AIP) academic journals and is traditionally known as o...

UiS researchers were awarded with scholarship

Only 34 young researchers around the world were selected to participate in the OMAE2023 Outreach for Engineers Forum. Th...

Large Offshore Wind Turbines: Structural design accounting for non-neutral wind conditions

How to reduce cost of energy for future large offshore wind turbines in free-wind and wake conditions by using full-scal...

Olympiad in Engineering Science summed up

Scientists and engineers from all over the world were gathered in Olympia in Greece to take part in the first ever engin...

UiS takes part in research on Arctic shipping

The goal is to find environmentally friendly solutions for shipping and transport in Arctic waters.

3 million for green offshore research

UiS researchers got funding for Polish-Norwegian collaboration.